Galvanized Metal Stud & Track Sheets Forming Making Line

Our Galvanized Metal Stud & Track Sheets Forming Making Line supports material thickness from 0.4-1.2 mm stud,track or carrying channel with the full engineering technicaldata/specification. Designed and pre-engineered by experienced truss specialists using only the very latest software. Normally our machine could make truss for Indian, Australia, Egypet and other countries. The shapes of the trusss are like furring hat shape, U shape, C shape, L shape and others.

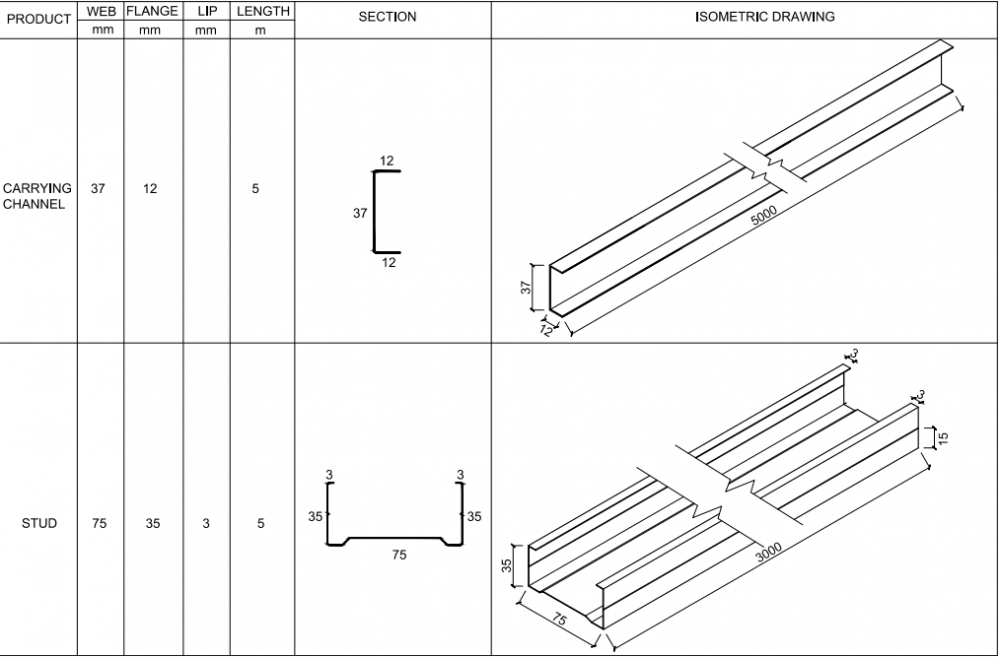

Drawing profile for you reference :

Component for Galvanized Metal Stud & Track Sheets Forming Making Line:

1. Decoiler one set

2. main roll forming machine one set

3. cutting and punching part

4. control box one set

5. hydraulic station

Details information for Galvanized Metal Stud & Track Sheets Forming Making Line:

Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system

Loading capacity: 1.5T

Uncoiling width: 300mm

Inner diameter: 450-550mm

Main roll forming machine:

Feeding and leveling will level coil to make sure it is neat clean and straight.

Size: 3800х800х1400mm

Weight t: 2.6 tons

Voltage:380V/50HZ3Phase(as customer`s request)

Roller fixer : Guide column

Frame : middle plate welded

Memorial arch frame type

Frame thickness:25mm

Speed: 5-50m/min

Drive mode: gear

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Number of rollers : 10rollers

Main power: 4kw

Shearing machine:

Material of blades: Gcr12 quenched

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Electric Control System:

Feature:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Hydraulic Station:

Hydraulic motor Power: 3kw

Hydraulic oil: 46#

Other mark:

1. Price: USD6500 to USD25000 /LINE FOB XINGANGCHINA

2. Payment: 30% T/T in advance and balance 70% after inspection confirmation before shipment.

3. One year, and we will provide the technical support for the whole life.

4. Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day for salary.

5. Need one technicians.

6. Training time: one week (contains the time of installation and adjustment)

Next: 50-70-100 perno prisionero y pista máquina C U canal que hace la máquina